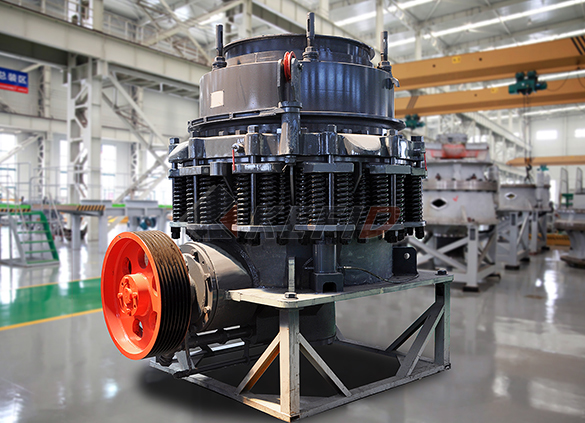

Mobile Crusher for Construction Aggregate Making

RAW MATERIAL: Limestone,Granite,Consruction Waste Recycle

CUSTOMERS SCORE: ★★★★★

PERFORMANCE: Improving Operational Efficiency,Increasing Profitability,Reducing Risks

The quality of fine aggregates or fine sand has the most important impact on concrete properties and production cost...

Mobile Crusher for Construction Aggregate Making

Construction aggregate, or aggregate, is a common material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and so on. Aggregate is a component of materials such as concrete and asphalt concrete. It adds strength to the composite material and is widely used in buildings, roads, and railways to ensure a stable foundation. Crushed stone or sand is main form of construction aggregate. Aggregates, concrete and construction waste can be recycled as aggregates as well.

Aggregate used in concrete mix, generally a coarse gravel or crushed rocks such as limestone, or granite, along with fine materials such as sand. Crushed stone and sand of specified sizes can be made by using crushers.

The quality of fine aggregates or fine sand has the most important impact on concrete properties and production costs. Fine aggregates can improve profitability in concrete production. Using Crushers and Screens from Kefid, you can significantly improve your profits and save costs.

Highlight:

1. The Latest Modular Design----Easy to Change Crusher or Spare Parts

Combined with easy replacement of main machines (crushers or spare parts) let you only need to re-invest for single main crusher when working situation changes.

2. Flexible Specification---From Coarse to Fine Crushing and Screening

Optimized production and diverse configuration programs perfectly adapt to various circumstances on working site. Simplified manufacturing process supports you for easy operation.

3. Energy Saving and Environment Protection

The speed-adjustable mode on trailer belts controls the conveying speed and reduces energy consumption according to handling capacity.

4. Over-Load Alarm System to Make Sure Operate Exactly

The Electrical signal Over-loaded alarm system make the power shutdown on time in case of failure, which reduces risks.

5. Durable Body Frame

The material steel for Crusher is upgraded from Q235A to Q345B. Its higher strength is suitable for low temperature(-25℃ to 40℃)environments.

See Some Requirements and Questions from Our Customers:

1.I need a price list for the mobile crusher to make gravel by using sedimentary rocks. And also some guidelines in setting up a gravel processing factory. I looked at the size of our raw material and I discovered that we have enough raw material that will sustain us for up to 6 years. The raw material is based on my land. That’s is the more reason why I want venture. We need to break down the mass of rock into frags.

2.I’m interested stone crusher with capacity of 5075 tons/ hour capacity along with screen and conveyor. What is your best quote along with option? This is for both building & road works.

3.I am looking for a 40-80tph granite crusher plant to process aggregates and produce coarse sand (0.6-2mm), crusher run (2-10mm), aggregate stone (10-20mm). Please advise on the budget price for such a plant.

4.I need a strong stone crusher for aggregates. I will say the output size should be 10-80mm.As its mobile the raw material is in range of dolomite to basalt. The higher output rate the better but should be in a range of 200-400tph. I will need to know the power requirements per output rate against the price.

5.Please give me some rough estimates of mobile crushers for aggregates you may have in the range and advise approx. price and daily outputs. We use final product as a sub base for roads mainly.

If you have the same requirements, questions or other questions about sand making, stone crushing, Please feel free to contact us. Our Manager will send you feedback in 24 hours by email.

Kefid will be with you throughout your entire operations. From financing, service agreements, trainings, maintenance. You can Leave us a message in the below form or chat with our online service.

Construction aggregate, or aggregate, is a common material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and so on. Aggregate is a component of materials such as concrete and asphalt concrete. It adds strength to the composite material and is widely used in buildings, roads, and railways to ensure a stable foundation. Crushed stone or sand is main form of construction aggregate. Aggregates, concrete and construction waste can be recycled as aggregates as well.

Aggregate used in concrete mix, generally a coarse gravel or crushed rocks such as limestone, or granite, along with fine materials such as sand. Crushed stone and sand of specified sizes can be made by using crushers.

The quality of fine aggregates or fine sand has the most important impact on concrete properties and production costs. Fine aggregates can improve profitability in concrete production. Using Crushers and Screens from Kefid, you can significantly improve your profits and save costs.

Highlight:

1. The Latest Modular Design----Easy to Change Crusher or Spare Parts

Combined with easy replacement of main machines (crushers or spare parts) let you only need to re-invest for single main crusher when working situation changes.

2. Flexible Specification---From Coarse to Fine Crushing and Screening

Optimized production and diverse configuration programs perfectly adapt to various circumstances on working site. Simplified manufacturing process supports you for easy operation.

3. Energy Saving and Environment Protection

The speed-adjustable mode on trailer belts controls the conveying speed and reduces energy consumption according to handling capacity.

4. Over-Load Alarm System to Make Sure Operate Exactly

The Electrical signal Over-loaded alarm system make the power shutdown on time in case of failure, which reduces risks.

5. Durable Body Frame

The material steel for Crusher is upgraded from Q235A to Q345B. Its higher strength is suitable for low temperature(-25℃ to 40℃)environments.

See Some Requirements and Questions from Our Customers:

1.I need a price list for the mobile crusher to make gravel by using sedimentary rocks. And also some guidelines in setting up a gravel processing factory. I looked at the size of our raw material and I discovered that we have enough raw material that will sustain us for up to 6 years. The raw material is based on my land. That’s is the more reason why I want venture. We need to break down the mass of rock into frags.

2.I’m interested stone crusher with capacity of 5075 tons/ hour capacity along with screen and conveyor. What is your best quote along with option? This is for both building & road works.

3.I am looking for a 40-80tph granite crusher plant to process aggregates and produce coarse sand (0.6-2mm), crusher run (2-10mm), aggregate stone (10-20mm). Please advise on the budget price for such a plant.

4.I need a strong stone crusher for aggregates. I will say the output size should be 10-80mm.As its mobile the raw material is in range of dolomite to basalt. The higher output rate the better but should be in a range of 200-400tph. I will need to know the power requirements per output rate against the price.

5.Please give me some rough estimates of mobile crushers for aggregates you may have in the range and advise approx. price and daily outputs. We use final product as a sub base for roads mainly.

If you have the same requirements, questions or other questions about sand making, stone crushing, Please feel free to contact us. Our Manager will send you feedback in 24 hours by email.

Kefid will be with you throughout your entire operations. From financing, service agreements, trainings, maintenance. You can Leave us a message in the below form or chat with our online service.