VU system strives to develop the standard of sand production, in terms of these three

core technic

index: graduation, shaped-size and sediment percentage.It can decrease

the voidage of sand production,

increasing its flowability and controlling the MB index,

so as to achieve the best concrete mixture ratio

and performance optimization.

Drying-processing conception is far more advanced than traditional wet-processing methods in terms of sand

performance,

environmental concern, investment value and so on. Throughout a series of creative

improvements, Kefid VU system provides

one-time solution for all the technical difficulties and achieve

the advanced dry-processing methods on sand production.

| Dry-processing | Wet-processing | Notes | |

| Performance of sand production | High | Low | High crushing ratio, meticulous screening with better adjusting ability improves the

standard of sand production level. |

| Enviromental concern | High | Low | Dry-processing method can apparently be zero released on dust and sludge. |

| Operation cost | Low | High | Dry processing conception has higher screening performance and automation degree,

less abbrasion and no polluted waste released. |

| Technicial difficulty | High | Low | Drying-processing method owns a completed system and it needs technicially and equipmentally upgrading. |

| One-off investment | A litele higher | Low | Higher requirement for equipments and investment. |

| Requirement for raw material | High | Low | Low moisture and low sendiment percentage is required for dry-processing conception. |

Excellent graduation, shaped-size and sediment percentage, stable and adjustable performance.

Washing sand device is not necessary. No polluted waste and dust. Land saving concern.

It can be produced by "stone pieces" and seeds-shaped waste, and other low-cost materials

Considerate and optimized production line concerning on the sand production ratio, labour force, electrical waste, spare parts, stability, etc.

Newly designed rotor with 5 holes, increase the frequency of material blasting.

Add grind block, form a integrated crush and grind function.

One-time sand making ratio and fine sand ratio would both rise to 10% or more.

Delete the chip needle shape material, and produce cubic shape material with smooth appearance. burr

Get the job done of vibrating, screening and de-dusting in one chamber.

Adjusting during the working process, module can controlled within 2.2-3.2.

Crush the material at low speed, in order to achieve pointy and crack hard spot crush.

Material in the shape optimizer can form a water-fall spiral movement, brush away the burr and scur.

Decrease the sand gap ratio to 1-2%, increase flowability to 5%, 0.15-0.6 granular composition content rise 5%

All seal production process, and negative-pressure could achieve the containing of powder, in order to detained them in the hopper, and realize zero-discharge.

Stone powder would be dry and clean, fineness is adjustable, according to the raw material could be considering put into extra values.

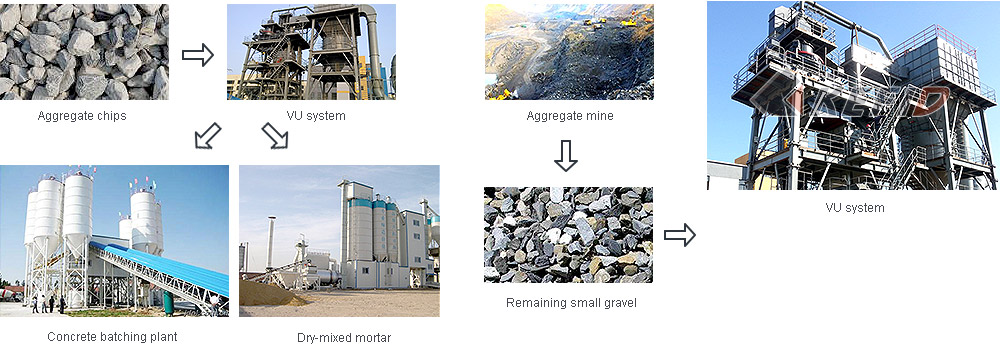

VU system processes the raw material, like tailings, rubbish and construction waste, with the dry method, which is controllable and environment friendly. The final products is comparable to the natural sand, which can meet the following requirements.

a. Operation is similar with the previous batching plant

b. Own-produce and own-use assure the

good-quality sand providing, optimizing the concrete mixing proportion.

c. Increase the interests

a.Processing the chips (large amount and lower sales ) from the mining processing.

b.Enrich the final

products, meet the downstream customers` needs for all kinds of aggregate.

| Model | Parameter | ||||

| Input size(mm) | Through capacity(t/h) | Final capacity(t/h) | Powder content (Adjustable) |

Power(KW) | |

| VU70K | 0-20 | 65-70 | 60-65 | 3-12% | 450 |

| VU120K | 0-20 | 110-120 | 100-110 | 3-12% | 830 |

Note: The above output will be changed according to the system parameters and material properties.