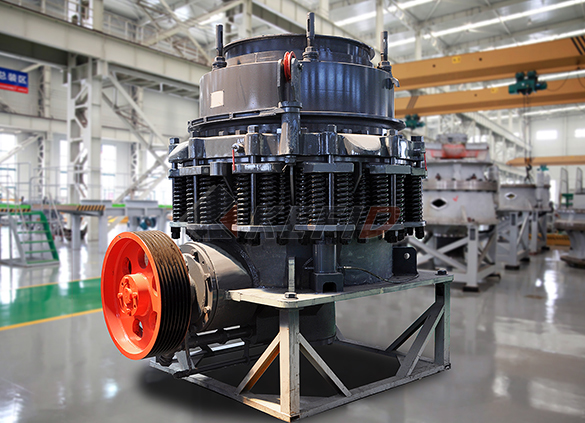

Rolling crusher in cement plant

RAW MATERIAL: Ore stone

CUSTOMERS SCORE: ★★★★★

PERFORMANCE: High capacity,high reliability,advanced technology and good stability,low running cost

Roll crushers are available in four model series with single-stage and two-stage designs. Roll crushers deliver high...

Roll crushers are available in four model series with single-stage and two-stage designs. Roll crushers deliver higher quality cubical product, minimal fines and consistently repeatable performance for sizing coal, coke, glass, fertilizer, potash, salts, lime, limestone, soft ores, friable materials and industrial minerals.

These roll crushers are available with Gundlach's breakthrough 3-D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry's best dimensional product control, fewer fines and elimination of over-size material.

Performance features of rolling crusher:

1. The structure is simple and compact, the noise is low, the efficiency is high.

2. The installation is flexible, basically needs no foundation.

3. The rollers' surface adopts anti-abrasive welding rod or exchangeable dental plate, the maintenance is simple.

4.This rolling crusher are widely applied to fine processing of building materials, metallurgy, chemical industry, coal etc crafts.

5. Especially applied to the finement of the clinker, adjusting the grinding mill grading can increase productivity 30-50%.

6. Self-preservation ability is strong, the high-hardness materials (such as all sorts of metal block) won't break the equipment's parts when they enter the shredding breach.

7. The discharge gram size is adjustable, the minimum can reach 2-10 mm.