Solution

The process of the Pulverizer system

Raw coal from the yard of raw coal through the sieve grid after falling to a large angle belt conveyor or hoist, the iron by the electromagnetic separator, the belt conveyor or hoist to the raw coal storage for storage.

To be flour milling system has been started, open the bottom of the original coal bar valve, seal gauge tape to start the coal, raw coal into the Xinjiang mill for drying, grinding.

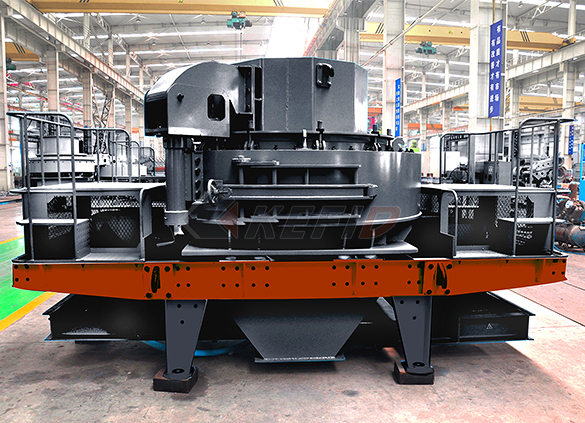

VM - Vertical Grinding Mill

The hot blast or exhaust gas coming out of the hot stove comes into the pulverizer of Xinjiang under the suction of the system fan and is fully heat-exchanged with the pulverized raw coal in the mill. After pulverized coal is separated at the separator, fine Degree of unqualified coarse pulverized coal fell onto the grinding wheel again, the qualified pulverized coal enters the explosion-proof air box pulsed dust collector with the air flow and was collected, and discharged into the pulverized coal silo after passing through the grid.

Raw materials in the debris, such as part of coal gangue, metal blocks, etc., through the wind ring, slag mouth out of Xinjiang mill mill outside.

There are oxygen and carbon monoxide detection devices in the production process. When processing coal with higher volatile content, a nitrogen system and a carbon dioxide fire extinguishing system are provided, which are safe and reliable.

If you have any questions or price about our machines,please feel free to chat with us!

Also you can contact us by phone or email any time!

E-mail: sales@kefidgroup.com

Phone: 0086-371-86537170(24 hours)