Solution

Wet sand or dry sand, which process is better?

In recent years, with the restriction of natural sand mining and the shortage of resources, artificial sand has gradually become the mainstream of the market. However, in the process of stone material processing, due to the intense collision and the fact that the stone material itself contains a certain amount of soil, the artificial sand contains a certain amount of stone powder and clay powder, which further affects the gradation of artificial sand. In order to solve the problem of containing powder, wet sand and dry sand appear.

Differences between the two:

1. Different devices for subsequent configuration

Wet sand making is a kind of sand making mode applied in sand washing machine.

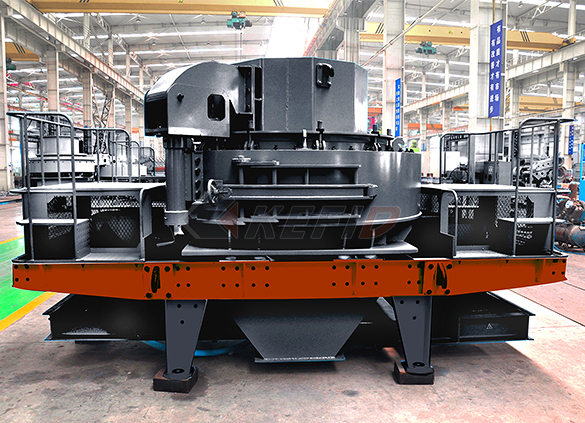

Dry sand is made by using the mill mode, so as to separate the sand powder, and finally select high-quality construction sand, dust will be collected as a by-product.

2. Different applicable regions

The wet sand method is applicable to areas with much water and close to water sources. Wet sand can build up sedimentation tank to achieve the purpose of recycling water resources, and also can be added to the fine sand recycling machine to collect the fine sand and sand powder in waste water.

Dry sand is used in dry areas far from water sources, such as the north.

3. Different investment costs

The dry sand production line adopts high efficiency separator to separate the sand powder. There is no need to add large amount of water cleaning in the production process, and the overall production cost will be relatively low.

In actual production, the choice of wet or dry sand depends on the region and water resources, the cleanliness of raw materials, and the specific requirements of aggregate, artificial sand powder content and fineness modulus.

If you are interested in the dry sand and wet sand solutions or equipment, welcome to consult our online customer service or call the hotline, we will serve you wholeheartedly!