NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

Non-metallic mineral milling process

Non-metallic mineral products is the industrial products which use non-metallic mineral as basic or main raw material and then made through deep-processing or finishing. There are numerous non-metallic minerals such as calcite, calcium carbonate, limestone, barite, talc, gypsum, graphite, kaolin, bentonite,etc. And its processing methods are generally crushing, grinding, finished products are used in industrial products production with the state of fine, superfine powder.

As Asia's largest and powerful crushing and milling equipment production and export base, Kefid designed systematic processing technic for non-metallic mineral milling technology.

Depending on the applications, non-metallic minerals are generally divided into four types of coarse powder processing (0-3mm), fine powder processing (20 mesh -400 mesh), ultrafine powder deep processing (400 mesh -1250 mesh) and micro powder processing (1250 mesh -3250 mesh).

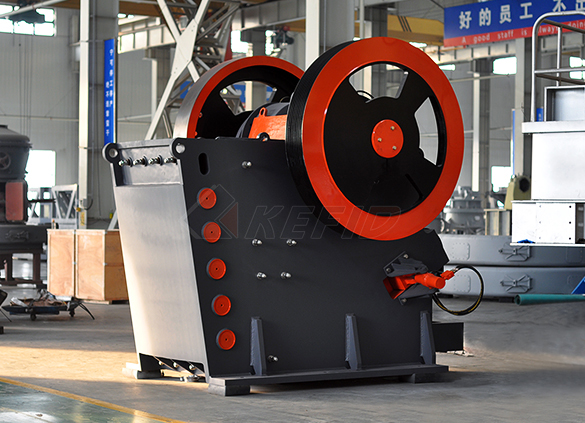

The first stage: crushing

Bulk material crushed by the crusher to be able to enter the mill feed fineness (15mm-50mm).

Second stage: milling

After crushing, small pieces of material are transferred to the hopper by elevator, and then sent by vibrating feeder uniformly into the grinding mill for grinding.

In equipment selection, Kefid series milling equipment can effectively use. CM European coarse powder mill can be used for coarse grinding, fine powder processing is generally use VM vertical roller mill, MTW European mill, TGM super pressure trapezium mill; ultrafine powder processing can use LUM ultra-fine vertical mill, HGM ultrafine powder mill.

Phase III: classification

After grinding,materials are selected by powder concentrator.Unqualified powder will return to the host for re-grinding.

Phase IV: collect powder

The qualified powder which in line with fineness with the airflow through the pipe into the dust collector to separate collection, finished powder collected through the discharge port from the delivery device to the finished product silos, and then unified with the loaded powder tanker or use automatic balers for packaging.

The entire process is a smooth and efficient system with green energy.We can provide strong technology and equipment to protect non-metallic mineral powder processing. Currently, Kefid has more than 10,000 milling production lines running around the world, continue to provide sufficient quality raw material for non-metallic mineral products.

More details about non-metallic mineral milling production lines and equipment, please contact our 24hour online customer service!