PERFORMANCE FEATURES

Low operation Cost

Learn more

1.Low operation Cost

(1)、High grinding efficiency: The roller grinds materials on the mill directly, which makes the energy consumption is 30%~40% less than the one of Bill Mill.

(2)、Little Wear: The roller and lining plate are made of premium material to have long service life.

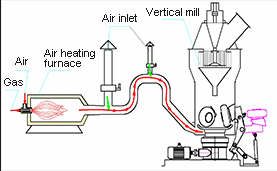

High Drying Ability

Learn more

Because the hot wind dries the materials in the mill, a drying machinery is saved. And the temperature of hot wind can be controlled to suit different moisture conditions of different materials.

The Stability of Product Quality

Learn more

The materials stayed shortly in the mill for easily detecting and controlling of the fineness and chemical composition of products, which can make the final size stable. There is few Ferric in final powder and the ferric content come from mechanical wear is easy to remove, the whiteness and purity is high, especial for processing white material.

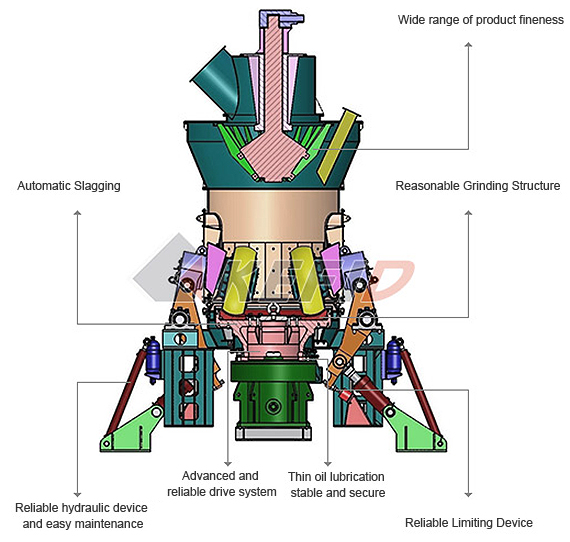

Thin oil lubrication

Learn more

The thin oil lubrication station attached to the mill makes the roller shafts lubricated circularly, providing them with a working environment of low temperature and pure lubrication oil, extending their service lives, and ensuring their stability.

Reliable hydraulic device

Learn more

Hydraulic device is adopted to control the acting force, and the acting force can be automatically adjusted according to different grindability of the raw material, which keeps the grinding mill in a perfect condition, not only reducing the consumption of the idle work, but also prolonging the using life of rollers and liners.

Advanced and reliable drive system

Learn more

The drive system consists of main motor, coupling and speed reducer. New-type Spiral bevel and planetary drive system are adopted by the speed reducer. The Babbitt thrust tile with strong wearability can bear more pressure load, which also increases the service life.

Auto-control system

Learn more

The mill is equipped with an auto-control system which allows PCL, centralized and DCS control, which makes the operation much easier and meets the different needs from the customers.

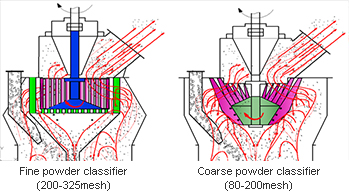

Wide range of product fineness

Learn more

Two different classifiers are adopted according to different material and different requirements for fineness. Meanwhile the frequency of the classifier is controllable, which ensures well-distributed particle size and higher product fineness.

Wide range of product fineness

Learn more

The mill makes small noises in its running because there is no direct contact between rollers and the grinding table, so it reduces 20-25 dB than that of ball mill. Plus, the vertical mill is totally sealed and the whole system works in negative pressure, making little dust.

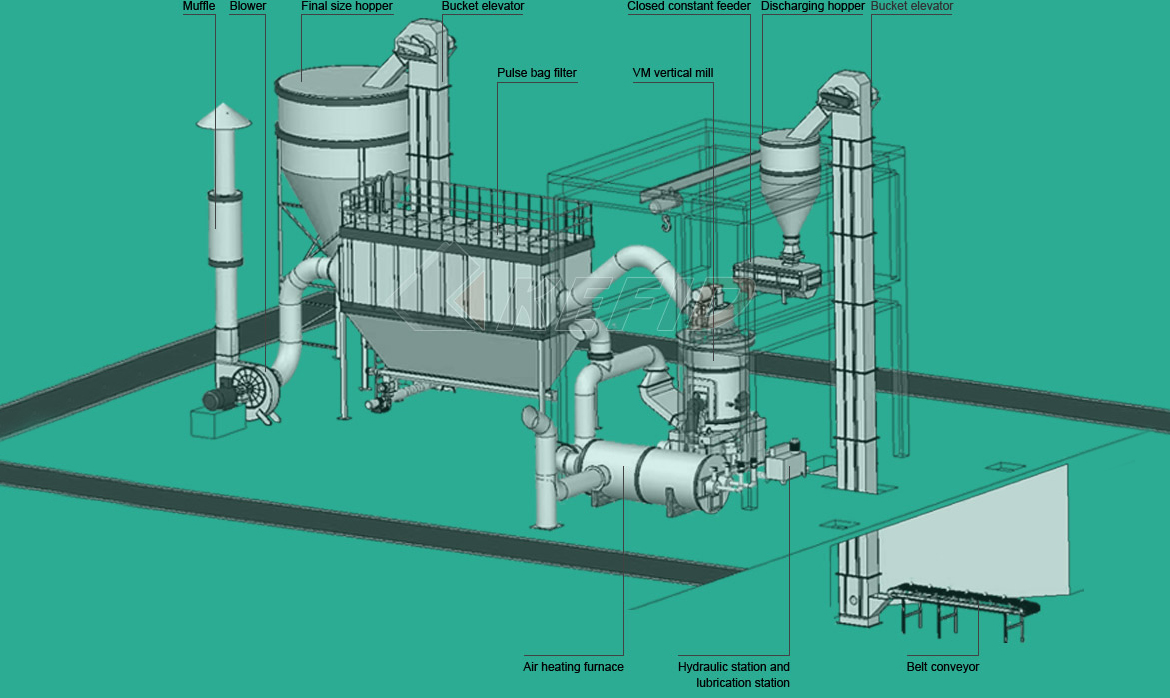

PRODUCTION PROCESS

PRODUCTION SITEVIEW MORE CASE

Quartz Sand Production Site:

Model : VM130K, Power: 200kw

Material :Silica

Production : 325mesh, 8-9 t/h

Working site : Indonesia

Feedback from Client :I bought other kind of grinding mill before , but the capacity is low which not meet our requirement . While this mill has higher capacity , the think-oil is convenient, no need to stop the machine for lubrication, it can work continuously. Also , easy to check , when changing the spare part ,only need half an day.

Limestone Production Site:

Model : VM190K, Power: 500kw

Material :Limestone

Production : 200mesh, 40-50t/h

Working site : Russia

Feedback from Client :This clients want to find a big capacity mill , after learning our working vertical mill principle , internal structure , characteristic, and our customer site , he order the VM190K, after that , we sent specialist engineer go to site for installation . The machine is now working in good condition , performance is stable .

Grinding Production Site:

Model : VM1500M, Power:280kw

Material :Coal

Production : 200mesh , 18-20t/h

Working site : China (One Power Plants) 5 years

Feedback from Client :Stable and reliable performance , can work 24 hours continuously, auto-control system saving lots of labor cost for us. convenient for assembly and disassemble. KEFID is a good supplier.

SPARE PARTS

Liner

Roller

Separator Blade

Classifier

SPECIFICATIONS

Mm to inch conversion: 25.4millimeters=1 inch

The humidity and hardness of raw material will affect the fineness and capacity.

| Contents|Data//Model | VM130k | VM150k | VM170k | VM190k | VM220k | |

| Capacity(t/h) | 10~28 | 13~38 | 18~48 | 23~68 | 36~105 | |

| Mainframe power(KW) | 200 | 280 | 400 | 500 | 800 | |

| Overall dimension | Length (mm) | 5520 | 6550 | 7170 | 7580 | 7920 |

| Width (mm) | 2500 | 3070 | 3460 | 3320 | 4870 | |

| Height (mm) | 7060 | 7560 | 8300 | 8960 | 12280 | |

| Weight(t) | 70 | 90 | 105 | 180 | ||

Notes:

1. Material should be with hardness less than 7 in Mohs'.

2. Hot air is only necessary if outlet moisture is required to be less than inlet moisture.

3.When grinding material is difficult to grind, please use the largest power.

| Content|arameter//Model | VM130M | VM150M | VM170M | VM190M | VM220M | |

| Wheel Diameter(mm) | 1300 | 1500 | 1700 | 1900 | 2200 | |

| Quantity of roller(piece) | 2 | 2 | 2 | 2 | 2 | |

| Capacity(t/h) | 10~17 | 16~22 | 20~30 | 26~40 | 35~50 | |

| Coal fineness(R0.08) | 5~20% | 5~20% | 5~20% | 5~20% | 5~20% | |

| Coal moisture | <1% | <1% | <1% | <1% | <1% | |

| Input size D80(mm) | <10 | <10 | <10 | <10 | <10 | |

| Max.input size(mm) | <38 | <40 | <42 | <45 | <50 | |

| Input moisture | <15% | <15% | <15% | <15% | <15% | |

| Inlet air temperature(℃) | <350 | <350 | <350 | <350 | <350 | |

| Outlet air temperature(℃) | 75~95 | 75~95 | 75~95 | 75~95 | 75~95 | |

| Hardgrove index of raw coal(HGI) | >55 | >55 | >55 | >55 | >55 | |

| Mainframe power(KW) | 185 | 250 | 315 | 400 | 500 | |

| Overall dimension | Length (mm) | 5520 | 4200 | 4700 | 7580 | 7670 |

| Width( mm) | 2500 | 3900 | 4500 | 3320 | 4660 | |

| Height (mm) | 7060 | 7100 | 8300 | 8960 | 11280 | |

| Weight(t) | 46 | 68 | 88 | 100 | 165 | |

Note: Any change of VM Vertical Mill technical data shall not be advised additionally.

| Content|Date//Model | VM130N | VM150N | VM170N | VM190N | VM220N | |

| Wheel Diameter(mm) | 1300 | 1500 | 1700 | 1900 | 2200 | |

| Quantity of roller (number) | 2 | 2 | 2 | 2 | 2 | |

| Capacity(t/h) | 5~14 | 7~20 | 9~27 | 12~30 | 18~55 | |

| Output fineness | Micron | 170~45 | 170~45 | 170~45 | 170~45 | 170~45 |

| Mesh | 80~325 | 80~325 | 80~325 | 80~325 | 80~325 | |

| Product moisture | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | |

| Input size D80(mm) | <10 | <10 | <10 | <10 | <10 | |

| Max.input size(mm) | <38 | <40 | <42 | <45 | <50 | |

| Input moisture(no need to dry) | <4% | <4% | <4% | <4% | <4% | |

| Input moisture(need to dry) | 4~15% | 4~15% | 4~15% | 4~15% | 4~15% | |

| Inlet air temperature(℃) | <350 | <350 | <350 | <350 | <350 | |

| Outlet air temperature(℃) | 70~95 | 70~95 | 70~95 | 70~95 | 70~95 | |

| Mainframe power(KW) | 200 | 280 | 400 | 500 | 900 | |

| Overall dimension | Length(mm) | 5520 | 6550 | 7170 | 7580 | 7920 |

| Width(mm) | 2500 | 3070 | 3460 | 3320 | 4870 | |

| Height(mm) | 7060 | 7560 | 8300 | 8960 | 12280 | |

| Weight(t) | 49 | 72 | 94 | 110 | 170 | |

: 0086-371-67988500 / 67999255 / 86537170(24 hours)

: 0086-371-67988500 / 67999255 / 86537170(24 hours) : sales@kefidgroup.com

: sales@kefidgroup.com : KFD_onlineservice

: KFD_onlineservice : kefidcrusher

: kefidcrusher : No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China

: No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China