Non-metallic mineral powder is now an important part of the new material, in the development of modern industry plays an important role. In recent years, non-metallic mineral powder industry gradually formed a larger scale, all kinds of non-metallic mineral powder annual output reached 100 million tons, and in high-tech materials industry, environmental protection industry and metallurgy, building materials, chemicals, , Paper, ceramics, plastics, composites, rubber and coatings and other industries have been widely used.

According to the different application areas, non-metallic mineral milling is generally divided into coarse powder processing (0-3mm), fine powder processing (20 mesh -400 mesh), superfine powder deep processing (400 mesh -1250 mesh) and powder processing (1250 mesh-3250 mesh) four types. Kefid in the absorption of foreign advanced technology on the basis of the company for many years the design concept and market demand for research and development made by the MTW Europeanl grinding mil, VM vertical grinding mill, TGM super pressure trapezium grinding and other milling equipment, professional for All kinds of non-metallic mineral grinding and upgrading, its performance has reached the international advanced level.

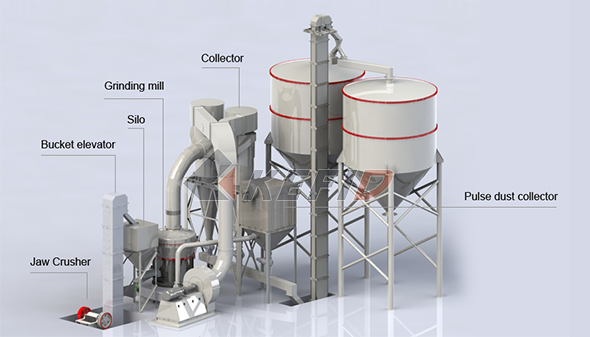

PROCESSING LINE

Non-metallic mineral milling process equipment : electromagnetic vibration feeder, jaw crusher, non-metallic mine mill, bucket elevator, belt conveyor, electronic control system, in order to achieve the desired environmental effects, Can also be equipped with pulse dust collector.

The bulk nonmetallic ore is crushed by the jaw crusher and sent to the storage silo by the bucket elevator, which is uniformly and continuously fed into the main body of the mill by the electromagnetic vibration feeder. The effect of the powder after grinding on the blower Under the blow to the separator for sorting. The fineness of the non-metallic mineral powder from the pipeline to the storage silo; unqualified particles back to the mill grinding. The entire system in the negative pressure state of operation, dust does not overflow, thus protecting the surrounding environment. If the filter by the pulse filter, environmental protection better.

Equipment

input size : 0-50mm

Capacity : 3-50T/h

Output size : 1.6-0.045mm, superfine up to 0.038mm

Advantages : Bevel gear overall drive reduce noise;Inner automatic thin-oil lubricating system makes better lubrication for bearings ; Unique air recycling system and dust collector make clean environment.

See Moreinput size : 0-65mm

Capacity : 10-320T/h

Output size : 20-425mesh

Advantages : This mill itself can crush,dry,grinding,classifying,so the system is simple ; With a limit device to avoid destructive shock and vibration ; Advanced transmission, high efficiency and environmental protection and energy conservation.

See MoreTGM Super Pressure Trapezium Mill

input size : 0-40mm

Capacity : 3-36T/h

Output size : 0.8-0.045mm,superfine up to 0.038mm

Advantages : Multi-step ladder-like roller and grinding ring design ; High density and high precision impeller device ; Efficient energy - saving centrifugal induced draft fan.

See MoreSUCCESSFUL CASES

Calcite deep processing project in Belgium

Raw Material : Calcite

Output Size : 800mesh=D90

Equipment : 2 sets MTW138 European grinding mills,PE250×400 Jaw crusher

Calcite deep processing project in Belgium

Raw Material : Calcite

Output Size : 800mesh=D90

Equipment :

2 sets MTW138 European grinding mills,PE250×400 Jaw crusher

Quartz powder processing project in HeBei of China

Raw Material : Quartz

Output Size : 200mesh

Equipment : VM1700 Vertical grinding mill

Quartz powder processing project in HeBei of China

Raw Material : Quartz

Output Size : 200mesh

Equipment :

VM1700 Vertical grinding mill

Non-metallic ore processing in southern China

Raw Material : Gypsum, Calcite

Output Size : 325mesh=D90

Equipment : TGM130 super pressure trapezium mill

Non-metallic ore processing in southern China

Raw Material : Gypsum, Calcite

Output Size : 325mesh=D90

Equipment : TGM130 super pressure trapezium mill

If there are any questions concerning the stone crushing & screening plant, please contact Kefid directly.

Our engineers will provide the professional solution. Welcome to visit our factory in Zhengzhou city, Henan province, China.

24-Hours Hotline:0086-371-64988500 E-mail:sales@kefid.com Click Online

: 0086-371-67988500 / 67999255 / 86537170(24 hours)

: 0086-371-67988500 / 67999255 / 86537170(24 hours)

: 0086-371-67998980

: 0086-371-67998980

: sales@kefid.com

: sales@kefid.com

: kefidmachine

: kefidmachine

: kefidcrusher

: kefidcrusher

: No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China

: No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China