PREFACE

Environmental protection is one of the most important topics in the 21st century. In recent years, with the development of the global economy, thermal power plants have sprung up, and coal combustion emissions of large amounts of SO2, NOx and CO2, resulting in worldwide acid rain, haze and other atmospheric environmental pollution problems are more serious, greatly Endanger our living environment. Therefore, to increase the thermal power plant on the SO2 control efforts is particularly important.

Thermal power plant desulfurization process commonly used is limestone - gypsum flue gas wet desulfurization, flue gas circulating fluidized bed, water film dust desulfurization integration technology. Among them, the limestone - gypsum flue gas desulfurization wet process (FGD) is the world's most mature technology, the most widely used control of SO2 emission technology, this technology developed in the forty or fifties of last century, the United States, Japan, Germany and other developed About 90% of the flue gas desulphurization units used in the country's thermal power plants use this process. Limestone - gypsum flue gas desulfurization wet process medium for the limestone powder, so the preparation of limestone powder has become a thermal power plant, steel desulfurization, improve the efficiency of desulfurization prerequisites.

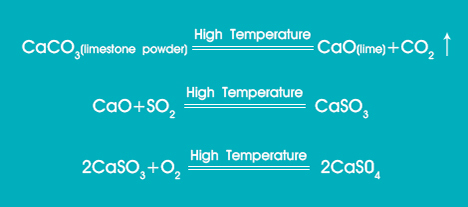

The chemical principle of limestone powder as desulfurizer

In the combustion of coal burning a certain proportion of limestone powder, after a series of chemical reactions, can achieve desulfurization effect.

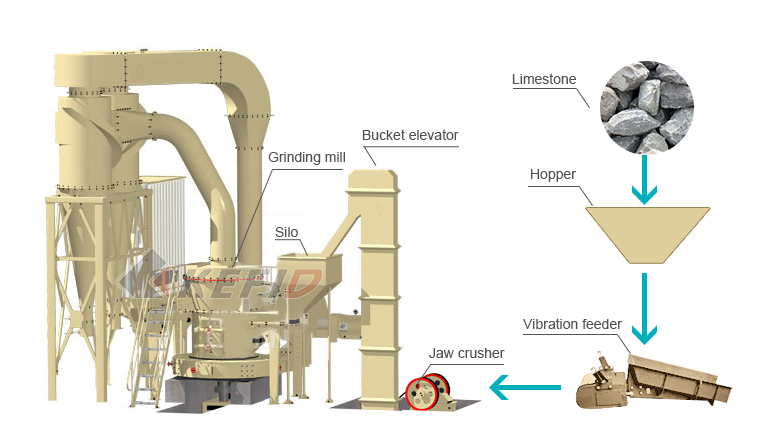

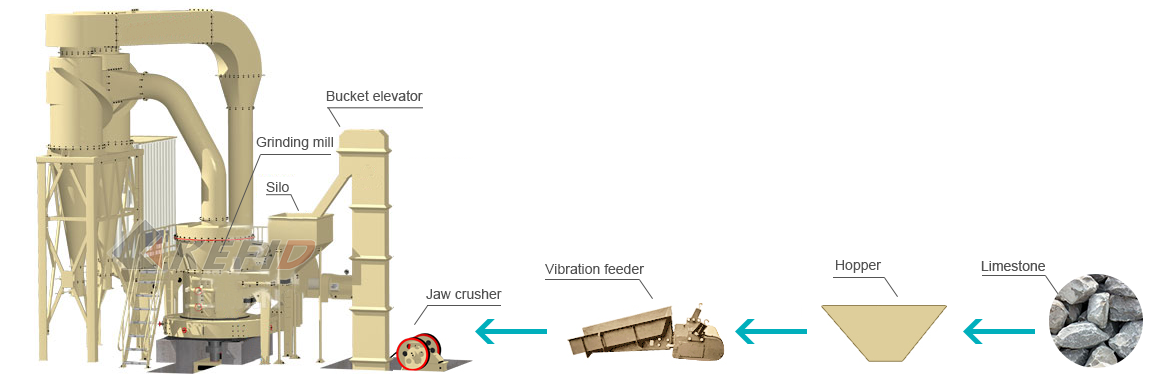

PRECESS FLOW

Kefid after years of research and use, developed desulfurization milling equipment and technology, high sulfur coal desulfurization rate can be more than 90%, desulfurization rate of low sulfur coal can be more than 95%.

The process is: large pieces of limestone crust jaw crusher to the required size, the bucket elevator to the storage hopper, and then by the vibration feeder evenly into the mill grinding. After the limestone powder was blown by the separator, grading, in line with the fineness of the limestone powder with the air into the whirlpool through the pipeline, the separation of collection. The collected limestone powder is fed from the conveyor to the stone silo for use in desulfurization. Unqualified particles in the powder after being separated from the cylinder wall, along the wall after the fall back to the mill inside the grinding. The entire system is running under negative pressure, dust does not spill to ensure cleanliness.

The process is: large pieces of limestone crust jaw crusher to the required size, the bucket elevator to the storage hopper, and then by the vibration feeder evenly into the mill grinding. After the limestone powder was blown by the separator, grading, in line with the fineness of the limestone powder with the air into the whirlpool through the pipeline, the separation of collection. The collected limestone powder is fed from the conveyor to the stone silo for use in desulfurization. Unqualified particles in the powder after being separated from the cylinder wall, along the wall after the fall back to the mill inside the grinding. The entire system is running under negative pressure, dust does not spill to ensure cleanliness.

EQUIPMENT SELECTTION

VM - Vertical Grinding Mill

OUTPUT SIZE : 80-325 mesh

PRODUCTION CAPACITY : Up to 128TPH(ore mill), up to 50TPH (coal mill)

APPLICATIONS : Glass fiber industry, coal industry, chemical industry, and for large scale powder making and non mental mine industry.

More

MTW Series European Grinding Mill

OUTPUT SIZE : 1.6-0.045 mm, the fineness is 0.038mm

PRODUCTION CAPACITY : 3.5-45T/H

APPLICATIONS : Cement, Coal , power plant desulfurization, metallurgy, Chemical Industry, non-metallic mineral, construction material, ceramics.

More

CASE

Limestone Line MTW215 grinding plant in Thailand

OUTPUT SIZE : 0.1-0.6mm

CAPACITY : 38t/h

EQUIPMENT : European tech grinding mill MTW215

Limestone Line MTW215 grinding plant in Thailand

OUTPUT SIZE : 0.1-0.6mm

CAPACITY : 38t/h

EQUIPMENT : European tech grinding mill MTW215

Limestone Line MTW215 grinding plant in Thailand

Near Moscow VM190K vertical mill

MATERIAL : Dolomite, Limestone

OUTPUT SIZE : 200 mesh

CAPACITY : 50 t/h

EQUIPMENT : Jaw crusher+Vertical mill

Near Moscow VM190K vertical mill

MATERIAL : Dolomite, Limestone

OUTPUT SIZE : 200 mesh

CAPACITY : 50 t/h

EQUIPMENT : Jaw crusher+Vertical mill

Near Moscow VM190K vertical mill

If there are any questions concerning the stone crushing & screening plant, please contact Kefid directly.

Our engineers will provide the professional solution. Welcome to visit our factory in Zhengzhou city, Henan province, China.

24-Hours Hotline: 0086-371-64988500 E-mail: sales@kefid.com Click Online

: 0086-371-67988500 / 67999255 / 86537170(24 hours)

: 0086-371-67988500 / 67999255 / 86537170(24 hours)

: 0086-371-67998980

: 0086-371-67998980

: sales@kefid.com

: sales@kefid.com

: kefidmachine

: kefidmachine

: kefidcrusher

: kefidcrusher

: No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China

: No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China