NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

Calcium oxide grinding process

Calcium oxide is an inorganic compound commonly known as quicklime. After being processed into fine powder by grinding, it can be used in the fields of fillers, building materials, refractories, desiccants,etc.

Different mills should be used for different fineness requirements of calcium oxide powder.

For ordinary fine powder of 80-400 mesh, it can be equipped with vertical mill and European type grinding mill. The MB5X intelligent European type mill is the sixth generation of pendulum raymond mill which is suitable for modern powder industrial production with high requirements for environmental protection.

If you want to process ultra-fine powder of 400 mesh or more, you can choose LUM ultra-fine vertical mill and MW micro-grinding mill. The processing range is between 400-2500 mesh, which is suitable for deep processing of calcium oxide powder.

Calcium oxide grinding process:

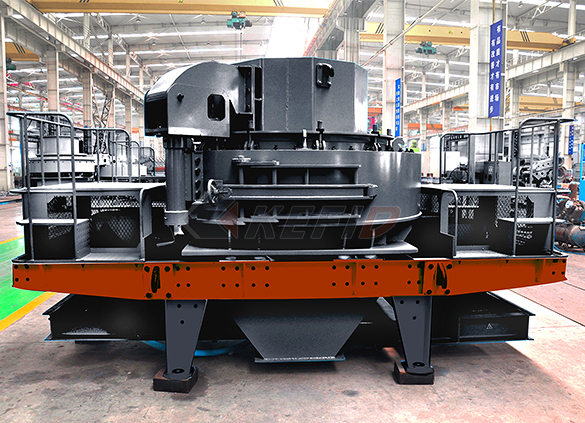

The first stage: crushing

The bulk calcium oxide is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

The second stage: grinding

The crushed small pieces of material are sent to the silo through the hoist, and then uniformly and quantitatively fed into the mill grinding chamber through the vibrating feeder for grinding.

The third stage: grading

The fine powder after grinding is classified by a powder concentrator, and the unqualified powder will be returned to the host for re-grinding.

The fourth stage: collecting powder

The qualified powder conforms to the airflow and enters the dust collector through the pipeline for separation and collection. The collected finished powder is sent to the silo through the discharge port, and then uniformly packaged by the powder tanker or the automatic baler.

More calcium oxide grinding mill details and quotations, please contact our 24hour online customer service.