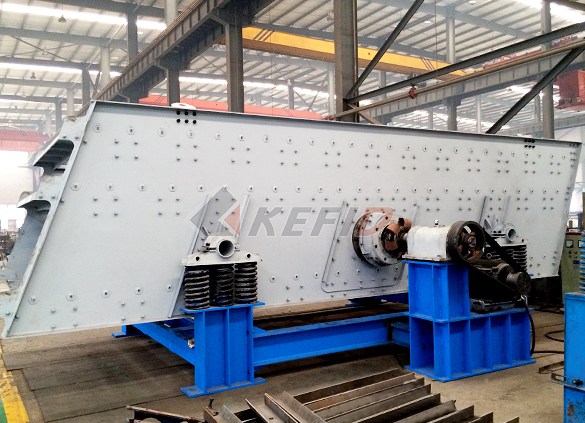

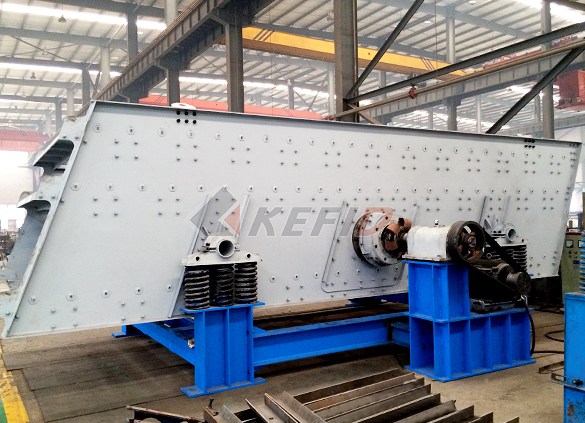

YK3X Series Vibrating Screen

YK3X Series Vibrating Screen

As the world’s leading manufacturer in the field of Mineral crushing, grinding and screening equipment, Zhengzhou Kefid Mechanical Industry Science & Technology Co., Ltd has installed tens of thousands of crushing, grinding & screening system all over the world since the end of 20th Century. Kefid launches the 3rd series vibrating screen: YK3X series variable circular vibrating screen, can apply to process the mineral rock with large size and big bulk density, such as aggregate making, metal ore processing, etc. YK3X vibrating screen is a new generation of products that have been perfected from the many years’ practices.

Output size : 5-150mm

Production capacity : 70-1300t/h

PROCESSED MATERIALS

Apply to the grading work of different mineral and rock with moisture less than 8%.

APPLICATIONS

Construction materials, mining processing, chemical industry, cement, etc.

PERFORMANCE

Features & Benefits:

1.The V-belt is connected with the intermediate driving shaft, the intermediate transmission bearing seat is connected with the vibration exciter by flexible coupling, effectively avoid the influence on the electric motor caused by the screen frame vibration, prolong the service life of electric motor.

2.All the side boards are connected with the cross beam and front & back cross arm by the ring-grooved rivets, overall uniform force, more reliable connection.

3.The intermediate transmission bearing seat is connected with the vibration exciter by the flexible coupling, so that the vibrating screen can work more stably without axial force of torque transmission.

4. The design of the screen frame adopts finite element analysis, so that the vibration parameters are larger, screening efficiency and processing capacity are larger.

5.Adopt the international advanced level synchronous belt structure, light weight and easy maintenance compared with the gear synchronizer.

6. Increase the excitation force relatively compared with the axis eccentric exciter, decrease the weight of vibration exciter, convenient for maintenance and replacement in site.